When it comes to finishing the edges of furniture and cabinetry, PVC edge banding is a popular choice due to its durability and versatility. If you're in the market for 3mm PVC edge banding, you may be wondering where to find the best quality products. In this guide, we'll explore everything you need to know about 3mm PVC edge banding, including where to find reputable factories and exporters.

1. Main Materials for Edge Banding

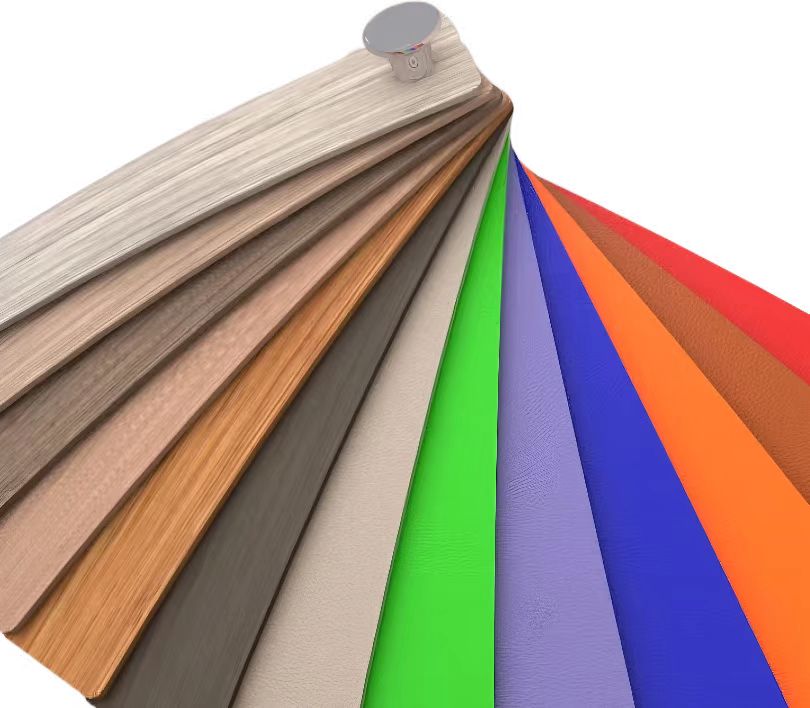

1. PVC Edge Banding

- Features: Most common, low cost, excellent waterproof and moisture-proof properties, wide range of colors.

- Disadvantages: Prone to shrinkage and aging under high temperatures, moderate environmental friendliness (contains small amounts of chlorine).

- Applications: Ordinary cabinets, non-high-temperature areas.

2. ABS Edge Banding

- Features: Non-toxic and environmentally friendly, good flexibility, heat-resistant, less prone to discoloration.

- Disadvantages: Higher cost, slightly lower wear resistance.

- Applications: High-end custom furniture, especially for children's rooms or spaces with high environmental requirements.

3. PP Edge Banding

- Features: Food-grade material, excellent environmental friendliness, heat-resistant, and corrosion-resistant.

- Disadvantages: Limited color options, relatively soft texture.

- Applications: Kitchens, bathrooms, and other humid environments.

4. Acrylic Edge Banding

- Features: High gloss, paint-like texture, good wear resistance.

- Disadvantages: High cost, difficult to process.

- Applications: Light luxury or modern-style furniture.

5. Solid Wood Edge Banding

- Features: Natural wood grain texture, highly environmentally friendly, can be sanded and repaired.

- Disadvantages: Prone to moisture deformation, expensive.

- Applications: Solid wood furniture or custom designs pursuing a natural style.

Edge Band Quality Assessment Standards:

1. Thickness Uniformity: High-quality edge bands have thickness errors ≤ 0.1mm, avoiding uneven edges.

2. Color and Texture Match: Minimal color difference from the board, with wood grain direction consistent.

3. Adhesive Line Visibility: PUR or laser edge banding has almost invisible adhesive lines, while EVA adhesive lines tend to turn black.

4. Wear Resistance Test: Lightly scratch with a fingernail; no visible marks indicate good quality.

5. Environmental Friendliness: Focus on formaldehyde release from edge bands and adhesives (must meet E0/ENF standards)

Common Issues and Solutions:

1. Edge Band Delamination

- Cause: Poor adhesive quality, insufficient temperature, or substandard process.

- Solution: Choose PUR adhesive or laser edge banding, avoid high-temperature and humid environments.

2. Blackened Edges

- Cause: EVA adhesive oxidation or edge band aging.

- Prevention: Use lighter-colored edge bands or PUR process.

3. Uneven Edge Band Joints

- Cause: Low equipment precision or human error.

- Suggestion: Select manufacturers of automated edge banding machines.

Purchasing Recommendations:

1. Material Selection Based on Scenario

- Kitchen, Bathroom: Prioritize PP or PUR edge-banded ABS material.

- Bedroom, Living Room: PVC or acrylic can be chosen, focusing on cost-effectiveness.

2. Pay Attention to Edge Banding Process

- For ample budget, choose PUR or laser edge banding, which increases durability by over 50%.

- Beware of small workshops' EVA edge banding, which is prone to delamination and poor environmental performance.

3. Brand Recommendations

- Imported: German Rehau, Durklin.

- Domestic: Huali, Weisheng, Wanhua (environmentally friendly PP edge bands).

Maintenance and Care:

- Avoid using sharp objects to scrape edge bands.

- Clean with a damp cloth, do not use strong acid or alkali cleaners.

- Regularly check edge band joints, repair any delamination promptly.

Edge banding, though small, is an essential detail in whole-house customization. It is recommended to prioritize eco-friendly materials such as ABS or PP, combined with PUR or laser edge banding techniques. This not only extends the lifespan of furniture but also reduces formaldehyde emissions. Before customization, it is imperative to clarify the edge banding material and process with the supplier and request to view samples or completed cases to ensure the final outcome meets expectations.

Post time: Mar-24-2025