When it comes to furniture design, every detail matters. From the material used to the finishing touches, each element plays a crucial role in the overall aesthetic and functionality of the piece. One often overlooked but essential component of furniture design is the edge banding. This is where custom OEM PVC edge options come into play, offering a versatile and durable solution to enhance the look and performance of your furniture.

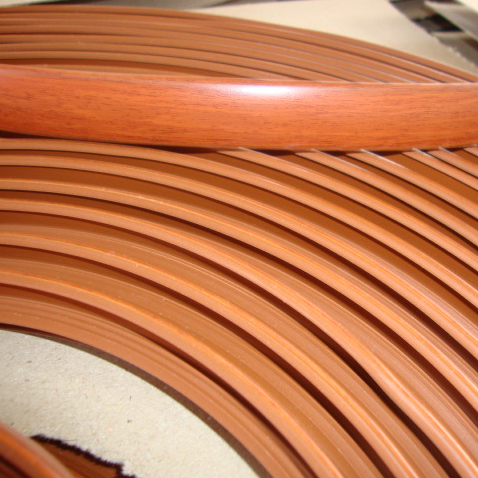

OEM PVC edge banding is a popular choice for furniture manufacturers and designers due to its versatility and durability. It is a cost-effective solution that provides a seamless and polished finish to furniture edges, protecting them from wear and tear while adding a touch of style. With custom OEM PVC edge options, designers have the flexibility to choose from a wide range of colors, textures, and finishes to complement their furniture designs.

One of the key benefits of using custom OEM PVC edge options is the ability to match the edge banding to the specific requirements of the furniture design. Whether it’s a sleek and modern look for contemporary furniture or a classic and elegant finish for traditional pieces, OEM PVC edge banding can be customized to meet the unique design needs of each project. This level of customization allows designers to create furniture that not only looks great but also performs well over time.

In addition to its aesthetic appeal, custom OEM PVC edge options offer practical benefits as well. PVC edge banding is highly durable and resistant to moisture, making it an ideal choice for furniture that is exposed to everyday wear and tear. It provides a protective barrier against impact, scratches, and other forms of damage, ensuring that the furniture maintains its appearance and functionality for years to come. This durability makes PVC edge banding a reliable choice for both residential and commercial furniture applications.

Furthermore, custom OEM PVC edge options can also contribute to the sustainability of furniture design. PVC edge banding is recyclable and can be manufactured using eco-friendly processes, making it a more environmentally conscious choice compared to other edge banding materials. By incorporating sustainable materials into furniture design, designers can reduce the environmental impact of their projects while still delivering high-quality and visually appealing furniture solutions.

Another advantage of custom OEM PVC edge options is the ease of installation and maintenance. PVC edge banding can be applied using a variety of methods, including hot air, hot melt, and pressure-sensitive adhesives, making it suitable for different types of furniture manufacturing processes. Once installed, PVC edge banding requires minimal maintenance, making it a practical choice for both manufacturers and end-users.

In conclusion, custom OEM PVC edge options offer a versatile and durable solution to enhance furniture design. With a wide range of colors, textures, and finishes to choose from, designers have the flexibility to create furniture that not only looks great but also performs well over time. The durability, practicality, and sustainability of PVC edge banding make it a reliable choice for a wide range of furniture applications. By incorporating custom OEM PVC edge options into their designs, furniture manufacturers and designers can elevate the quality and appeal of their products while also contributing to a more sustainable approach to furniture design.

Post time: Jul-18-2024