In the world of furniture manufacturing, the use of high-quality materials is essential to creating durable and visually appealing products. One such material that has gained popularity in recent years is OEM PVC edge. This versatile material offers a wide range of benefits that make it an ideal choice for furniture manufacturers looking to enhance the quality and aesthetics of their products.

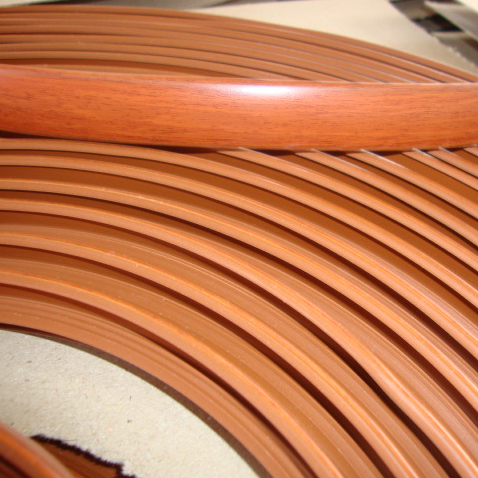

OEM PVC edge is a type of edge banding that is made from polyvinyl chloride (PVC) and is specifically designed for use in furniture manufacturing. It is available in a variety of colors, textures, and thicknesses, making it suitable for a wide range of applications. Whether you are producing office furniture, kitchen cabinets, or residential furnishings, OEM PVC edge can be customized to meet your specific design requirements.

One of the key benefits of using OEM PVC edge in furniture manufacturing is its durability. PVC is known for its strength and resistance to wear and tear, making it an excellent choice for edge banding. When applied to the edges of furniture, OEM PVC edge provides a protective barrier that helps prevent chipping, cracking, and other forms of damage. This not only extends the lifespan of the furniture but also reduces the need for costly repairs and replacements.

In addition to its durability, OEM PVC edge offers excellent moisture resistance. This is particularly important for furniture that is used in kitchens, bathrooms, or outdoor settings, where exposure to moisture is common. The moisture-resistant properties of PVC edge banding help prevent warping, swelling, and other forms of water damage, ensuring that the furniture maintains its structural integrity and appearance over time.

Another advantage of using OEM PVC edge is its ease of maintenance. Unlike natural wood or other materials that require regular sealing and refinishing, PVC edge banding is virtually maintenance-free. It can be easily cleaned with a damp cloth and mild detergent, allowing for effortless upkeep and ensuring that the furniture retains its like-new appearance for years to come.

Furthermore, OEM PVC edge offers a high degree of design flexibility. With a wide range of colors and textures available, furniture manufacturers can customize the look of their products to suit different styles and preferences. Whether you prefer a sleek, modern aesthetic or a more traditional, wood-like finish, PVC edge banding can be tailored to achieve the desired visual impact.

From a manufacturing standpoint, OEM PVC edge is also easy to work with. It can be cut, shaped, and applied using standard woodworking tools and techniques, making it a cost-effective and efficient choice for furniture production. Its flexibility and adaptability allow for seamless integration into various furniture designs, enabling manufacturers to achieve precise and polished edges with minimal effort.

In terms of environmental sustainability, OEM PVC edge offers several advantages. PVC is a recyclable material, and many manufacturers offer eco-friendly options that are made from recycled PVC. By choosing PVC edge banding, furniture manufacturers can contribute to the reduction of waste and the conservation of natural resources, aligning with the growing demand for sustainable and eco-conscious products.

In conclusion, the use of OEM PVC edge in furniture manufacturing offers a multitude of benefits, including durability, moisture resistance, ease of maintenance, design flexibility, ease of use, and environmental sustainability. By incorporating PVC edge banding into their production processes, furniture manufacturers can enhance the quality, longevity, and visual appeal of their products, ultimately satisfying the needs and preferences of their customers. As the demand for high-quality, long-lasting furniture continues to grow, OEM PVC edge stands out as a reliable and advantageous choice for the modern furniture industry.

Post time: Jun-21-2024