If you are in the manufacturing industry, you are likely familiar with the term OEM PVC edge. OEM, which stands for Original Equipment Manufacturer, refers to companies that produce parts and equipment that are used in the products of another company. PVC edge, on the other hand, is a type of edging material that is commonly used in furniture manufacturing. In this ultimate guide, we will explore everything you need to know about OEM PVC edge, including its uses, benefits, and considerations for choosing the right supplier.

Uses of OEM PVC Edge

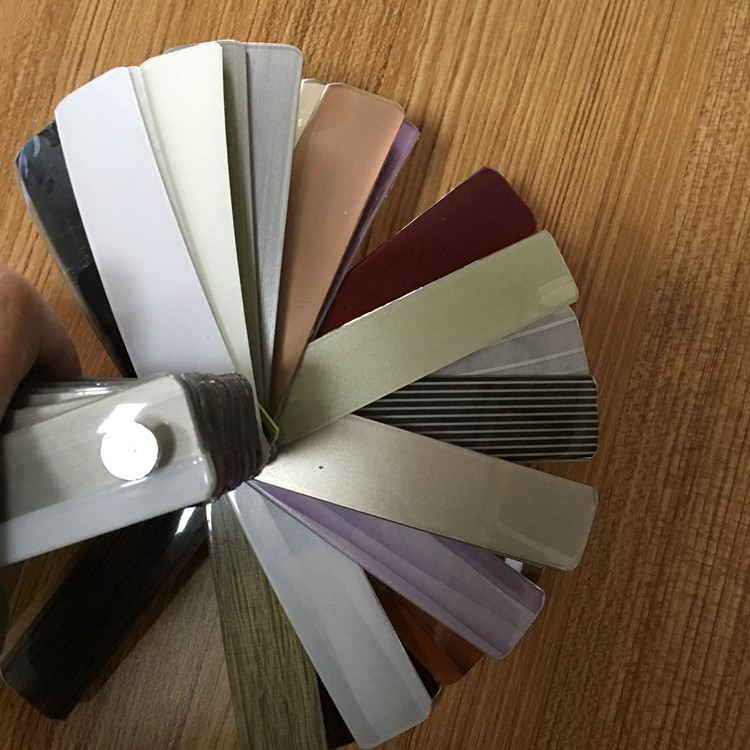

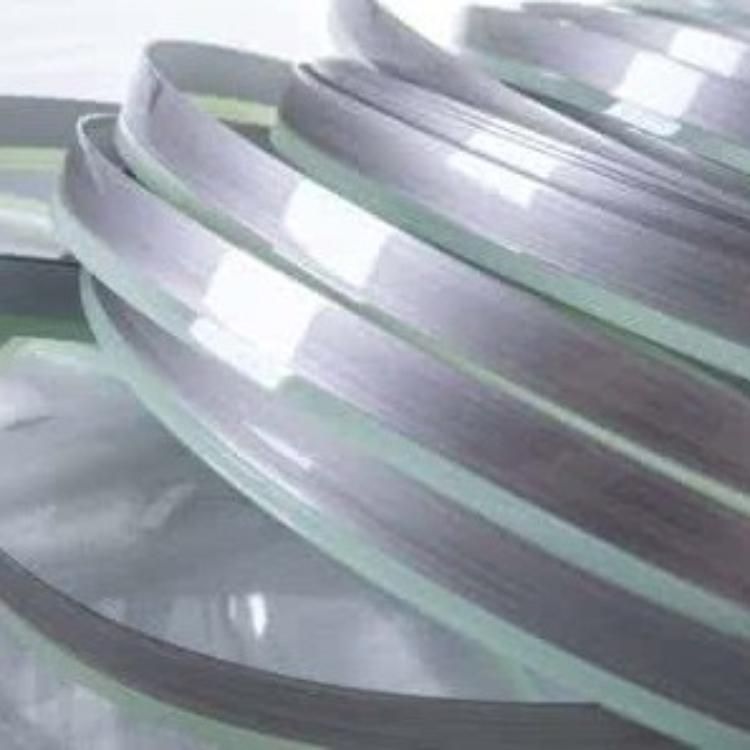

OEM PVC edge is widely used in the manufacturing of furniture, cabinetry, and other wood-based products. It is used to cover the exposed edges of panels, providing a clean and finished look to the final product. PVC edge is available in a variety of colors, textures, and thicknesses, making it a versatile choice for different applications. Whether you are producing office furniture, kitchen cabinets, or retail displays, OEM PVC edge can be customized to meet your specific design requirements.

Benefits of OEM PVC Edge

There are several benefits to using OEM PVC edge in manufacturing. One of the main advantages is its durability. PVC edge is resistant to moisture, chemicals, and impact, making it suitable for both indoor and outdoor applications. It is also easy to clean and maintain, which is important for products that are subject to regular wear and tear. Additionally, PVC edge is cost-effective compared to other edging materials, making it an attractive option for manufacturers looking to reduce production costs without compromising on quality.

Considerations for Choosing the Right Supplier

When it comes to sourcing OEM PVC edge, choosing the right supplier is crucial. There are several factors to consider when evaluating potential suppliers. First and foremost, you should look for a supplier that offers a wide range of customization options, including color matching, embossing, and custom profiles. This will ensure that the PVC edge aligns with your design specifications. Additionally, you should consider the supplier’s production capabilities and lead times to ensure that they can meet your manufacturing schedule. Quality control and consistency are also important factors to consider, as you want to ensure that the PVC edge meets your quality standards every time.

In addition to these factors, it is important to consider the supplier’s commitment to sustainability and environmental responsibility. Look for a supplier that uses eco-friendly materials and manufacturing processes to minimize the environmental impact of the PVC edge production. This can be an important selling point for manufacturers who are looking to align with sustainable practices and meet the demands of environmentally conscious consumers.

Conclusion

OEM PVC edge is an essential component in the manufacturing of furniture and wood-based products. Its versatility, durability, and cost-effectiveness make it a popular choice for manufacturers looking to achieve a high-quality finish while optimizing production costs. When sourcing OEM PVC edge, it is important to consider factors such as customization options, production capabilities, quality control, and sustainability. By choosing the right supplier, manufacturers can ensure that they are getting a high-quality product that meets their design requirements and aligns with their environmental values. With this ultimate guide, you are now equipped with the knowledge you need to make informed decisions when it comes to OEM PVC edge sourcing and production.

Post time: Jun-07-2024