When it comes to finishing off the edges of furniture and cabinetry, there are a few different options to choose from. Two popular choices are ABS edge banding and PVC edge banding. While both options serve the same purpose, there are some key differences between the two that consumers should be aware of.

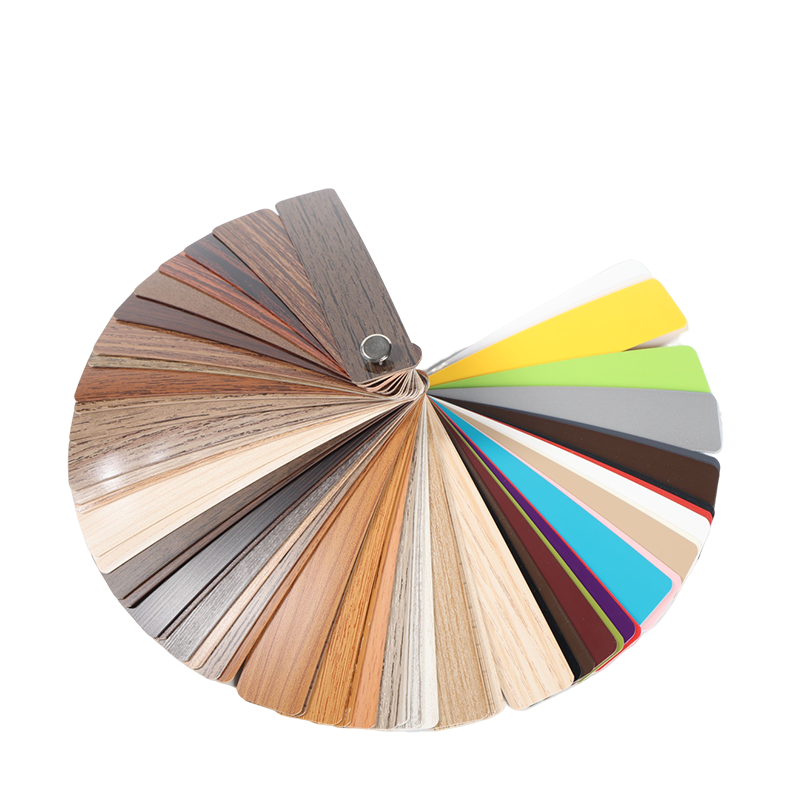

ABS edge banding, which stands for acrylonitrile butadiene styrene, is a thermoplastic polymer that is known for its strength and durability. It is commonly used in the manufacturing of automotive parts, electronics, and household appliances, as well as in the production of edge banding for furniture and cabinetry. ABS edge banding is available in a wide range of colors and finishes, making it a versatile option for different design aesthetics. It is also resistant to moisture and chemicals, making it a popular choice for kitchen and bathroom applications.

PVC edge banding, which stands for polyvinyl chloride, is a type of plastic that is known for its flexibility and cost-effectiveness. It is commonly used in the manufacturing of pipes, cables, and construction materials, as well as in the production of edge banding for furniture and cabinetry. PVC edge banding is available in a wide range of colors and finishes, and it is also resistant to moisture and chemicals, making it a popular choice for kitchen and bathroom applications.

One of the main differences between ABS edge banding and PVC edge banding is their composition. ABS edge banding is made from a blend of three different plastics: acrylonitrile, butadiene, and styrene. This gives it a high level of strength and durability, making it suitable for high-traffic areas. PVC edge banding, on the other hand, is made from a single type of plastic: polyvinyl chloride. While PVC edge banding is flexible and cost-effective, it is not as durable as ABS edge banding and may be more prone to damage in high-traffic areas.

Another difference between ABS edge banding and PVC edge banding is their environmental impact. ABS edge banding is a recyclable material, which means that it can be repurposed and used again at the end of its lifecycle. PVC edge banding, on the other hand, is not easily recyclable and can have a negative impact on the environment if it is not disposed of properly. This is an important consideration for consumers who are looking to minimize their environmental footprint.

In terms of installation, both ABS edge banding and PVC edge banding can be easily applied to the edges of furniture and cabinetry using hot air or adhesive methods. However, ABS edge banding is known for its ability to be easily machined and shaped, making it a popular choice for manufacturers and installers who are looking for a material that is easy to work with. PVC edge banding, on the other hand, may require a bit more effort to cut and shape, which can add to the overall installation time and cost.

When it comes to cost, PVC edge banding is generally more affordable than ABS edge banding, making it a popular choice for budget-conscious consumers. However, it is important to consider the long-term durability and environmental impact of the material before making a decision based solely on cost.

In conclusion, both ABS edge banding and PVC edge banding have their own set of advantages and disadvantages. While ABS edge banding is known for its strength, durability, and environmental sustainability, PVC edge banding is flexible, cost-effective, and easy to work with. Ultimately, the choice between the two will depend on the specific needs and priorities of the consumer, as well as the intended application of the edge banding.

Mark

JIANGSU RECOLOR PLASTIC PRODUCTS CO., LTD.

Liuzhuang Twon Industrial Park, Dafeng District, Yancheng, Jiangsu, China

Tel: +86 13761219048

Email: [email protected]

Post time: Feb-03-2024